为了校核俄罗斯阿穆尔气体处理站项目舱体结构设计的合理性,采用有限元仿真的方法,建立舱体的3维有限元仿真模型,进行静止平放状态下舱体承力框架、地脚螺栓的强度及计算分析;进一步的,分析舱体吊装状态下的舱体、起吊点和吊具强度。通过有限元仿真数据的处理,对关键结构件的强度及变形进行分析,最后给出变形及强度校核结果。

3D finite element simulation model is built by the method of finite element simulation to calculate and analyze the strength of cabin bearing frames and anchor bolts in static placement, thus verifying the reasonability of the cabin structure design in the Russia Amur Gas Treatment Station Project, to further analyze the strength of the cabin, hoisting points and hoisting tools in hoisting state. The strength and deformation of key structural components are analyzed by processing finite element simulation data to finally present deformation and strength verification results.

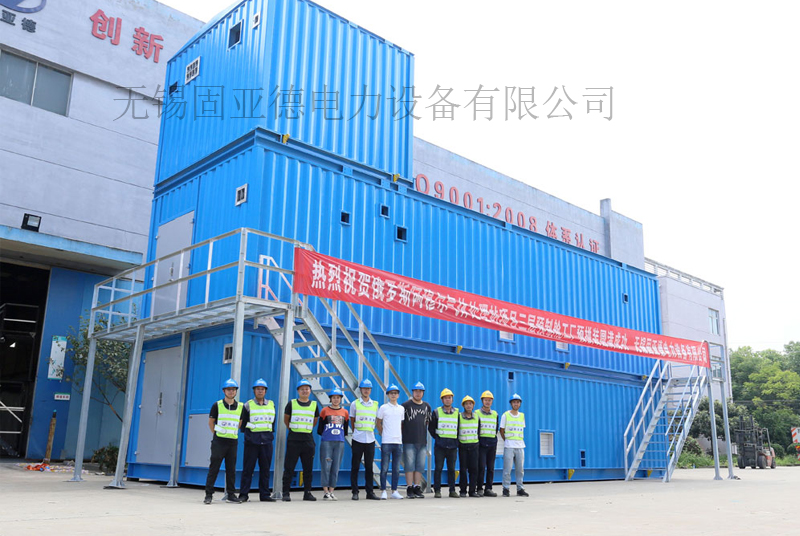

舱体总体尺寸:15m(总长)×4.5 m(宽)×10.5m(总高),其中一层高2.8m、二层高3.5m(含坡顶3.75m)、三层高3.32m(含坡顶3.75m)。

Overall dimension of cabin: 15m (overall length) ×4.5m (width) ×10.5m (overall height), wherein the first layer is 2.8m high, the second layer 3.5m high (3.75m including slope top) and the third layer 3.32m (3.75m including slope top).